Uncategorised

Mechanical Shearing Machine

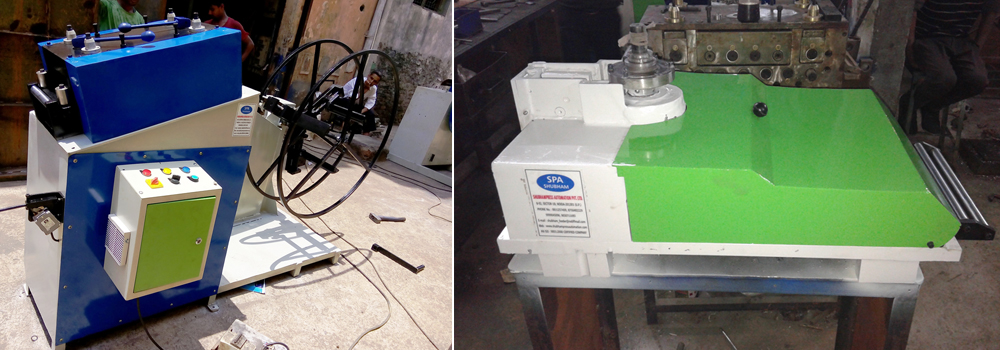

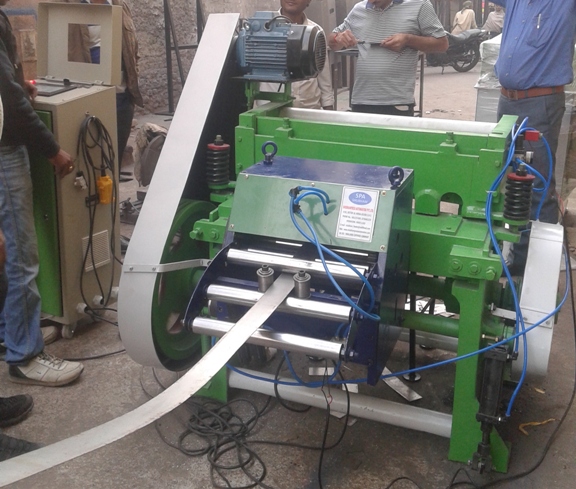

Mechanical Shearing Machine Manufacturers : We are manufacturer of Mechanical shearing mechanical over cranks and under Cranks. These are fabricated from superior quality raw material and are available in different shearing lengths and capacity of cutting thickness. Our range integrates automatic lubrication system, ball roller or ball transfer, foundation bolts, extension squaring arm and other accessories. We have Wide Range of Mechanical Shearing Machines With high-grade raw material and Latest Technologies. We are one of the Leading Mechanical Shearing Machine Manufacturers and Suppliers in India because of our Competitive Pricing and Superior Quality.

FRAME : The Frame is rigidly constructed from Solid steel plates with safeguards, It's interlocked design provides support to the bed directly on the frame to avoid weak sections at load supports.

HOLD DOWN SYSTEM : Spring Loaded mechanical Hold Down system are provided to hold the sheet securely to avoid slipping and bowing allowing a clear and accurate cuts.

KNIVES : Each Mechanical Shearing Machine is provided with high quality single segment, (HcHcr) knives for enhanced tool life. The knive blades are four edged.

MECHANICAL BACK GAUGE : Mechanical Back Gauge is operated by Rack Pinion arrangement for easy and accurate cutting operations. The Front gauge moves on a "T" slot provided on the table.

FINGER GUARD : To avoid accident, Finger Guard is fitted in front of Hold down system for operator's protection without obstructing his view.

LUBRICATION : All moving parts of Mechanical Shearing Machines are provided lubrication by hand operated pump for smooth operation.

STANDARD ACCESSORIES : Gear & Wheel Guard, Hand operated back Gauge, Manual Lubrication pump, Stroke counter, T-Slot front supporters, front Scale gauge.

OPTIONAL ACCESSORIES : Automatic Lubrication system, Electric Motor, Starter, V-Belt, Ball Roller or ball transfer, Foundation Bolts, Extension squaring arm etc.

| Business Type | Exporter, Manufacturer, Importer, Supplier |

| Export Percentage | 65% |

| Import Percentage | 15% |

| No of Staff | 75 |

| Year of Establishment | 2012 |

| No of Production Lines | 15 |

| Export Markets | Middle East |

| South East Asia | |

| USA | |

| Import Markets | Europe |

| Taiwan | |

| OEM Service Provided | Yes |

| No of Engineers | 25 |

| Monthly Production Capacity | As Per Client's Requirements |

| Product Range | Mechanical Gripper Feeder |

| NC Servo Roll Feeder On Press | |

| DeCoiler and Uncoiler | |

| Beval Gear Type Motorized De-Coiler | |

| Motorized DeCoiler | |

| Hydraulic Motorized DeCoiler | |

| Double Side Non Motorized DeCoiler | |

| Double Cone Type Hydraulic Motorized DeCoiler | |

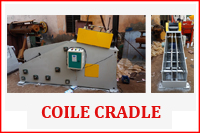

| 2 In-1 DeCoiler Cum Straightener | |

| 2 In-1 DeCoiler Cum Straightener (Cradle Type) | |

| 3 In-1 DeCoiler Cum Straightener | |

| Pneumatic Air Feeder | |

| Strip Straightener | |

| Cut To Length Line | |

| Slitting Line | |

| Die Lifter | |

| Zig Zag Nc Servo Roll Feeder | |

| New Air Feeder Word Number One | |

| Material Handling Equipment, etc. | |

| Product Export | Quality products |

| Industry leading prices | |

| Diligent workforce | |

| Vast clientele. |

We, “Shubhampress Automation Private Limited,” are counted as the leading manufacturer, exporter and supplier of a wide range of Decoiler, Straightener, Pneumatic Air Feeder, MTC- Series With Coil Loading Car, NC Servo Roll Feeder, Zig Zag NC Servo Roll Feeders, Mechanical Gripper Feeders, High Speed Gear Change Feeder, Coil Handling Hydraulics Lifter Machine, Cut To Length Line, etc. We design and manufacture these products using premium quality raw material, sourced from the well-established vendors of the industry. These products are widely demanded and appreciated by our clients, owing to the features like fine finish, optimum quality, durability and reliability. We manufacture these products in compliance with the set international quality standards in our high-tech manufacturing unit. Our precious clients can avail these products in various specifications as per their specific requirements and at highly competitive prices.

Our organization is backed by the supporting highly skills and experienced team of performance, which assists in fulfilling the needs of our clients in an efficient manner. Under the guidance of Mr. Ram Singh, we have been able to maintain a strength foothold in the industry. His vast-experience and constant motivation have enabled us to serve our clients in the best possible manner.

Aim / Vision / Mission

Our mission is to provide professional quality services on time and on budget. And Develop a follow-up strategy to gauge performance with clients.

Our Team

Our team consists of highly experienced engineers in different stages of production. Our team is divided as per the units of production like planning, requirement gathering & analysis, designing, metal sheet cutting by using various cutting machines, integration , quality checking and maintenance. Before delivering all kind of equipments we test the machine in our manufacturing unit. And we do quality checking at each stage of production. Our team includes:

- Quality inspectors

- Engineers

- Technicians

- R&D

- Marketing representatives

- Skilled and semi skilled

Client Satisfaction

We have been able to etch an enviable position in the world where quality and creativity excels. Our clients have always appreciated our work as we try to fulfill their needs and requirement with quality products. During the procurement process, we make sure our range not only meet the industrial standard but also available in affordable price. We select our vendor after rigorous assessment on their past records as it helps us in catering quality products to our diverse clients. The feed back of our clients is also important for us as it help us in knowing the pros and cons. We also provide following amenities to our clients:

- Quality product

- Cost effectiveness

- Timely delivery

- Quality packaging

- Easy payment mode

Quality Assurance

Quality is the most important attribute of our organization, and thus we make sure that it is not compromised at any stage. Owing to our quality, we have been accredited with the prestigious ISO 9001:2008 certification. This is the reason why we have been able to garner such a vast client base across the globe. We make sure that the raw material used is of the optimum quality and that our range is designed in compliance with the requirements of our clients. The team of quality inspectors keep a tab on the whole process. These are further tested for quality various times, so that a flawless range is delivered to our clients.

Why Us?

We known for timely delivery, we have gained a vast client base in the market. Some of the factors behind our success are as follows:

- State-of-the-art manufacturing facility

- Stringent quality control norms

- Industry leading prices

- Reliable products

- Timely delivery

- Customized solutions

Coming Soon

HIGH SPEED GEAR CHANGE FEEDER

|

FEATURES

High cam mechanismHigh speed and high precision feeding, speed up to 40M min Reliable and stable feeding One year quality gurantee |

Option function

Cam options is 3,4,8,12division feeding

length is chosen according to the cam

division and gear ration , this system is

suitable multitudinous for production

|

|

MODEL |

GCF-100 |

GCF-210 |

GCF-300 |

GCF-400 |

|

STOCK WIDTH(mm) |

100 |

210 |

300 |

400 |

|

STOCK THICKNESS (mm) |

|

|

0.3~2.0 |

|

|

CAM DIVISION |

|

|

3/4/8/12 |

|

|

FEEDING LENGTH (mm) |

|

|

1.20~600 |

|

|

FEEDIING ANGLE |

|

|

180 |

|

|

RELEASE ANGLE |

|

|

135~120% |

|

|

FEEDING DIRECTION |

|

|

LEFT TO RIGHT |

|