Uncategorised

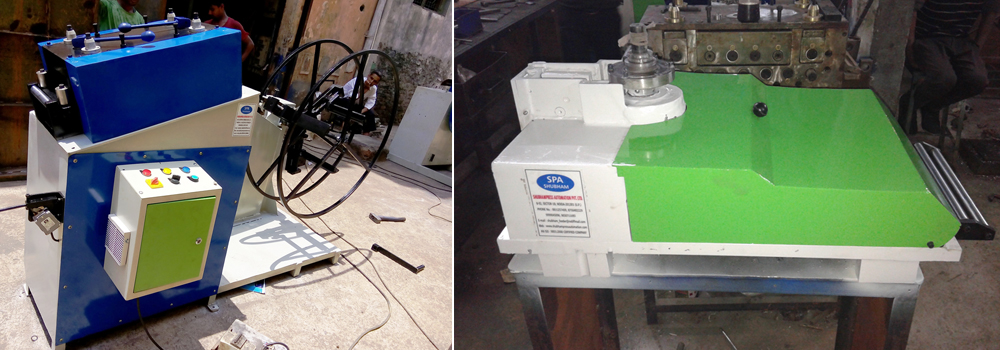

Cut To Length Line

We are engaged in manufacturing, exporting and supplying an excellent quality Cut To Length Line. Our product range also comprises Pneumatic Air Feeder, Decoiler, Straightener, Motorised Decoiler, Non-Motorised Decoiler, Decoiler cum Straightener and Nc Servo Roll Feeder. The offered product is manufactured using top-notch quality raw material and advanced machines. This product is available in standard and customized specifications at affordable prices. Further, our quality controllers firmly check the quality of product as per the set industry standards. Clients can avail this product from us at most reasonable prices.

Cut to Length Line Machine

We are a leading manufacturer, exporter and supplier of high quality Cut To Length Line. This product is used for processing both ferrous and non-ferrous material. It is fabricated by our professionals using high grade factor inputs and latest technology in conformity with international quality standards. The offered range is thoroughly tested by our quality controllers in order to ensure its flawlessness.

Cut to Length Line Features:

- Cut to length lines varies from 400 mm to 2500 mm

- Width Coil thickness varies from 0.20 mm to 16 mm (CRC, HR, CRNGO & S.S. Material)

- Weight of Coil varies from 3.0 ton to 30 tons

- Operation : Hydraulic Power and Pneumatic Clutch

- Construct : Made up of EN-31 material, alloy steel-roller, hardened gears etc.

- Control Line : Electrical Stopper line NC Servo Motor based Line.

- Control Line Encoder : PLC Based

Minimum Order Quantity: 01 Piece

Delivery Time: 60 days

Coil Handling Hydraulics Lifter Machine

Company expertise lies in manufacturing, exporting and supplying a wide assortment of Coil Handling Hydraulics Lifter Machine. For the fabrication of this product, our professionals make use of high quality raw material and advanced technology. Our offered product is tested on well-defined parameters of quality in order to ensure flawless. In addition to this, we offer this quality tested product to our precious clients at market leading prices.

|

Hydraulic hand pallet truck Capacity

2500 to 5000kgs.

|

Stacker

|

|

|

HYDRAULICS LIFTER MACHINE

|

U-model floor crane Capacity –

1100x2200x3000mm

|

|

|

Drum stacker Capacity

300kgs.

|

Coil Handling Hydraulics Lifter Machine

We are recognized as foremost manufacturer, exporter and supplier of premium quality Coil Handling Hydraulics Lifter Machine. This product finds application in various industries. Offered product is designed by our experienced professionals as per the latest trends of the market. The offered product is fabricated using the best grade raw material and sophisticated technology. Further, we offer this product in different specifications as per the stipulations provided by clients.

Coil Handling Hydraulics Lifter Machine Features:

- Premium quality

- Durability

- Reliability

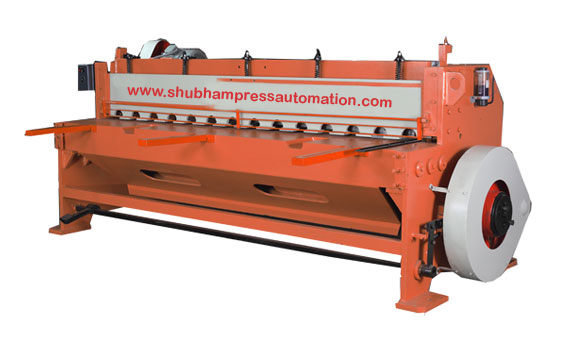

Mechanical Under Crank Shearing Machine

Shubhampress Automation Mechanical Under Crank Shearing Machine have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability.

Frame : Rigid steel frame of Shubhampress Automation shears are optimally designed to avid weak sections at load supports and is of interlocked design. The ram is guided throughout its length by hardened and ground guide ways ensuring proper clearance and clean cut.

Hold-Down System : Spring loaded mechanical hold-down pads hold the sheets securely to avoid slipping and bowing result in clean square cut. Hold down units are provided with oversize pads to avoid impression on sheet metal.

Blades : Shubhampress Automation shear are provided with Four Edge, single & segment ally High Carbon, Chromium Steel Blades suitable for M.S. &.S.S. Cutting and Extra long life.

Lubrication : All bearing parts and guide surfaces are lubricated Through centralize hand-operated lubrication system.

Mechanical Back Gauge : This is a standard equipment provided on all Shubhampress Automation Shears. Scale on the back gauge gives instantaneous reading of distance between shear and back gauge, thus avoiding errors and maintenance encountered in electronic equipment.

Finger Guard : Fitted in front of hold-down for operator safety without obstructing viewing.

Standard Equipment : Electrical System consisting of motor & Control Panel of Starter, Gear and wheel guard, V-Belts, Hand operated back gauge, Manual Lubrication System, T-slot front gauge, Front scale gauge, instruction Manual

Optional Equipment : Hydraulic hold-down system, Automatic lubrication system, Ball roller or Ball Transfer, Foundation bolts, Extension squaring arm.

Note : Electrical and Blades are not under Warranty.

Mechanical Guillotine Shearing Machines :

"Shubhampress Automation" brand mechanical shearing machines are available in two versions i.e. under crank and over crank having capacities starting from 500 mm to over 3000 mm and with thickness varying from 2 to 12mm. Machines incorporate several standard, optional features like hold down systems- mechanical, hydraulic manual or auto lubrication systems- mechanical back gauge; ball roller or ball transfers; extension squaring arm finger guard etc. Special versions can also be offered to meet specific production requirements.

Mechanical Over Crank Shearing Machine

Shubhampress Automation Mechanical Over Crank Shearing Machine have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability.

Frame : Rigid steel frame of Shubhampress Automation shears are optimally designed to avid weak sections at load supports and is of interlocked design. The ram is guided throughout its length by hardened and ground guide ways ensuring proper clearance and clean cut.

Hold-Down System : Spring loaded mechanical hold-down pads hold the sheets securely to avoid slipping and bowing result in clean square cut. Hold down units are provided with oversize pads to avoid impression on sheet metal.

Blades : Shubhampress Automation shear are provided with Four Edge, single & segment ally High Carbon, Chromium Steel Blades suitable for M.S. &.S.S. Cutting and Extra long life.

Lubrication : All bearing parts and guide surfaces are lubricated Through centralize hand-operated lubrication system.

Mechanical Back Gauge : This is a standard equipment provided on all Shubhampress Automation Shears. Scale on the back gauge gives instantaneous reading of distance between shear and back gauge, thus avoiding errors and maintenance encountered in electronic equipment.

Finger Guard : Fitted in front of hold-down for operator safety without obstructing viewing.

Standard Equipment : Electrical System consisting of motor & Control Panel of Starter, Gear and wheel guard, V-Belts, Hand operated back gauge, Manual Lubrication System, T-slot front gauge, Front scale gauge, instruction Manual

Optional Equipment : Hydraulic hold-down system, Automatic lubrication system, Ball roller or Ball Transfer, Foundation bolts, Extension squaring arm.

Note : Electrical and Blades are not under Warranty.

Mechanical Guillotine Shearing Machines :

"Shubhampress Automation" brand mechanical shearing machines are available in two versions i.e. under crank and over crank having capacities starting from 500 mm to over 3000 mm and with thickness varying from 2 to 12mm. Machines incorporate several standard, optional features like hold down systems- mechanical, hydraulic manual or auto lubrication systems- mechanical back gauge; ball roller or ball transfers; extension squaring arm finger guard etc. Special versions can also be offered to meet specific production requirements.